Enhancing Manufacturing Processes: The Influence of 3D Laser Scanning on Quality Assurance

3D laser scanning modern technology is transforming quality assurance in manufacturing. By supplying high-resolution information and specific dimensions, it allows suppliers to identify deviations from specifications with simplicity. This innovation not just simplifies evaluation procedures yet additionally enhances operational effectiveness. 3D Scanning. The implementation of this innovation comes with its very own set of challenges. Checking out these elements reveals the broader implications for industries and the future landscape of production

Recognizing 3D Laser Scanning Innovation

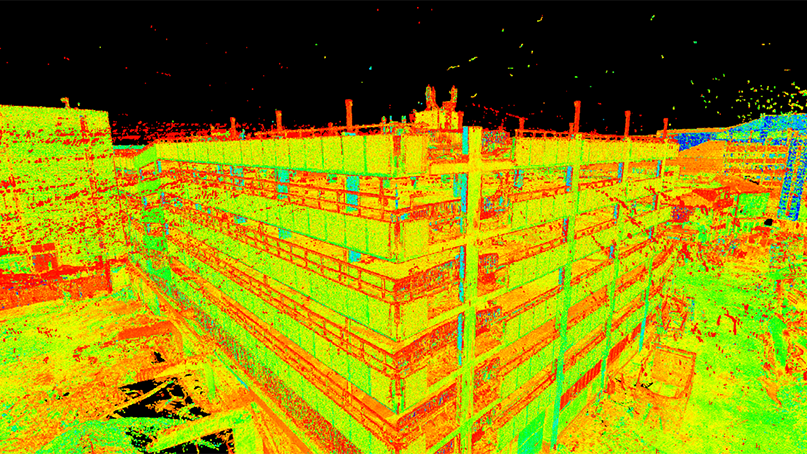

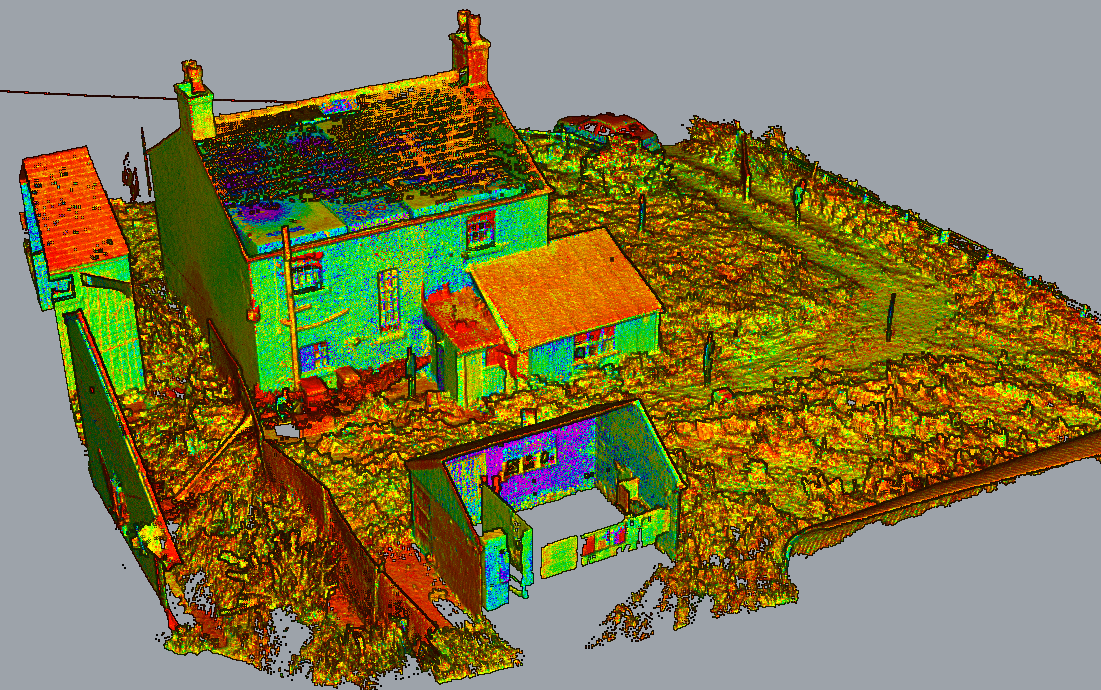

Although 3D laser scanning modern technology has advanced considerably in the last few years, its fundamental principle remains simple: recording the precise geometry of items making use of laser beams. This innovation utilizes laser light to gauge ranges between the scanner and various points on an item's surface area. The data accumulated is then processed to produce a thorough 3D model, accurately reflecting the dimensions and contours of the scanned object.

Typically, 3D laser scanners can be categorized into two main types: contact and non-contact scanners. Contact scanners physically touch the challenge gather measurements, whereas non-contact scanners use laser light beams to capture data from a range. The versatility of this technology enables its application across various industries, consisting of design, manufacturing, and building. Its capability to produce high-resolution models facilitates top quality control, reverse design, and fast prototyping, ultimately boosting style accuracy and effectiveness in production procedures.

Advantages of 3D Laser Scanning in Manufacturing

As manufacturers seek to boost effectiveness and precision in their processes, the advantages of 3D laser scanning have become increasingly noticeable. This ingenious modern technology permits very precise and fast measurements of intricate geometries, significantly minimizing the moment needed for top quality checks. By capturing detailed information, manufacturers can recognize inconsistencies early in the manufacturing process, therefore lessening waste and revamp prices.

Furthermore, 3D laser scanning helps with better layout validation, enabling engineers to compare as-built problems with original specifications. This capability ensures that any kind of inconsistencies are quickly resolved, improving total product high quality. Additionally, the technology supports the production of electronic twins, which can be used for simulations and procedure optimizations. As an outcome, manufacturers not only enhance their functional performance but likewise improve their affordable benefit on the market. Generally, the assimilation of 3D laser scanning stands for a transformative step toward accomplishing greater criteria in making quality assurance.

Integration of 3D Laser Scanning Into Quality Assurance

Integrating 3D laser scanning right into high quality control procedures boosts the accuracy and effectiveness of examinations throughout manufacturing. This modern technology makes it possible for producers to capture in-depth, high-resolution data of settings up and components, permitting accurate measurements and comparisons against design specifications. By using 3D laser scanning, companies can recognize inconsistencies from tolerances a lot more successfully, which is crucial for preserving product integrity.

Real-World Applications and Instance Researches

Real-world applications of 3D laser scanning in manufacturing demonstrate its transformative impact across various industries. For example, aerospace companies utilize this innovation to conduct accurate evaluations of elements, ensuring they meet strict security requirements. A noteworthy case involved a leading aircraft supplier that used 3D laser scanning to simplify its quality assurance procedures, substantially minimizing assessment times and errors.

In the automotive sector, suppliers have actually carried out laser scanning to produce digital doubles of their lorries, making it possible for real-time changes throughout production. One automobile firm reported a 30% reduction in rework prices after integrating this technology right into their assembly lines.

In the consumer products industry, business are using 3D laser scanning for fast prototyping, allowing for quicker models and enhanced item designs. These applications highlight just how 3D laser scanning not only boosts accuracy yet also improves performance and advancement across several manufacturing domains.

Overcoming Challenges in Application

Implementing 3D laser scanning in producing presents numerous challenges that companies have to navigate to completely understand its benefits. One substantial difficulty is the preliminary cost of equipment and software program, which can deter business from embracing this technology. Additionally, integrating 3D laser scanning right into existing operations requires conquering resistance to change among employees, demanding detailed training programs to guarantee efficiency. Information monitoring additionally poses a challenge, as the high volume of info produced by 3D scanning need to be effectively processed and assessed to acquire workable insights. Moreover, compatibility issues with tradition systems may impede seamless combination, demanding prospective upgrades or adjustments. Dealing with these obstacles is vital for makers intending to improve quality assurance and enhance production procedures. By establishing clear strategies for training, financial investment, and information administration, firms can minimize these barriers and launch the transformative capacity of 3D laser scanning in their operations.

Future Fads in 3D Laser Scanning for Production

As producing remains to evolve, the assimilation of 3D laser scanning with boosted automation is expected to change manufacturing processes. Enhanced information analytics will play a vital duty in boosting and enhancing workflows quality control. These fads highlight the capacity for greater performance and precision in producing environments.

Increased Automation Combination

Although the assimilation of automation in production has actually been gradual, the future of 3D laser scanning is poised more info to accelerate this pattern considerably. As making procedures come to be increasingly complex, the demand for exact, real-time dimensions grows. 3D laser scanning technology provides automated data capture, decreasing labor expenses and lessening human error. This combination enables makers to enhance high quality control procedures, allowing fast detection of discrepancies in production. Furthermore, the positioning of 3D laser scanning with robotics and automated systems assists in smooth operations, enhancing overall efficiency. As manufacturers adopt these innovative modern technologies, they can anticipate enhanced accuracy and productivity, placing themselves competitively in a swiftly developing market. The synergy in between automation and 3D laser scanning notes a considerable leap onward in making advancement.

Improved Data Analytics

The assimilation of automation has paved the means for improvements in data analytics within the domain name of 3D laser scanning. Producers are increasingly leveraging innovative algorithms and artificial intelligence techniques to assess huge datasets generated by laser scans. This boosted information analytics capability permits real-time monitoring of making processes, making it possible for the identification of defects and variances much more effectively than standard methods. Anticipating analytics can foresee possible issues, substantially minimizing downtime and boosting general effectiveness. Furthermore, the capability to envision data in 3 measurements supplies much deeper insights right into manufacturing process, cultivating better decision-making. As 3D laser scanning innovation remains to progress, the duty of data analytics will come to be increasingly important in driving development and keeping competitive benefit in production.

Frequently Asked Concerns

What Industries Benefit one of the most From 3D Laser Scanning?

The markets that benefit most from 3D laser scanning include production, building and construction, aerospace, automotive, and healthcare. These markets use the modern technology for precision measurements, top quality guarantee, and reliable layout procedures, substantially boosting total functional performance.

Just How Does 3D Laser Scanning Contrast to Traditional Measurement Techniques?

3D laser scanning uses greater precision and speed contrasted to standard measurement methods. It captures detailed geometries quickly, decreasing human error and helping with much better analysis, which ultimately enhances total quality assurance in numerous sectors.

What Is the Price of Carrying Out 3D Laser Scanning Innovation?

The cost of implementing 3D laser scanning modern technology varies considerably, typically varying from $10,000 to $100,000, relying on training, tools, and software program. Organizations needs to weigh these costs versus potential effectiveness and top quality improvements.

Are There Certain Software Program Requirements for 3D Laser Scanning?

Yes, 3D laser scanning calls for particular software program, consisting of data processing and modeling applications. Typical options include CAD software application, point cloud handling devices, and specialized applications that facilitate the assimilation and evaluation of checked data for suitable results.

Just how Lengthy Does a Common 3D Laser Scanning Refine Take?

A typical 3D laser scanning process can take anywhere from a couple of mins to several hours, depending upon variables like the size of the item, intricacy of the setting, and required level of detail for precision.

3D laser scanning technology is transforming high quality control in production. 3D laser scanning modern technology has developed significantly in current years, its basic principle remains simple: catching the specific geometry of objects using laser beams. Integrating 3D laser scanning into high quality control procedures improves the precision and performance of inspections throughout manufacturing (3D Scanning). 3D laser scanning technology offers automated data capture, decreasing labor expenses and lessening human error. The expense of applying 3D laser scanning modern technology differs substantially, generally ranging from $10,000 to $100,000, depending on equipment, software application, and training